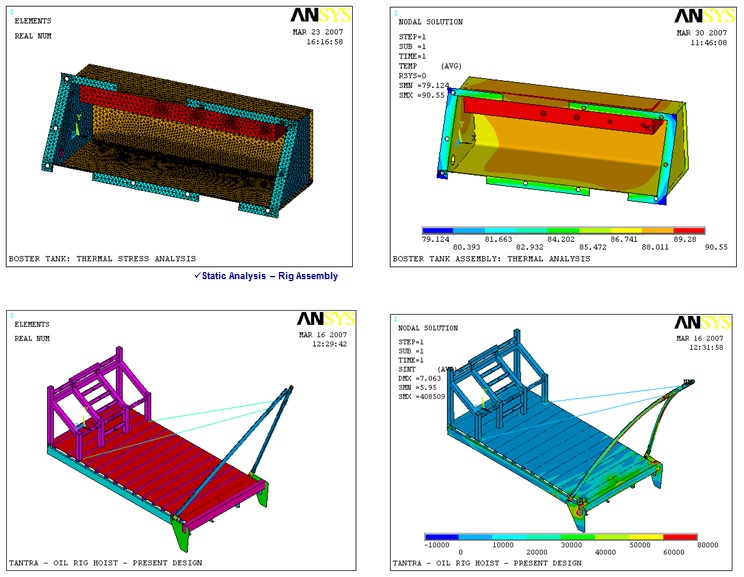

Finite element analysis (FEA) is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow and other physical effects. Finite element analysis shows whether a product will break, wear out or work the way it was designed. It is called analysis, but in the product development process, it is used to predict what is going to happen when the product is used.

TOI investigates and determines required design intent and evaluate through calculations resulting in thoroughness and accurate report summaries and inferences.

TOI’s FEA results in quickly testing many design variations and optimize products and systems in the virtual environment. Expertise and hands on skill in performing the analysis with precise inputs lies with TOI analyst’s ownership.

Capabilities in FEA (Finite Element Analysis):

- Linear Static Analysis

- Non-Linear Static Analysis

- Non-Linear Contact Stress Analysis

- Normal Modal / Frequency Response Analysis

- Transient Structural Analysis: Strength, Fatigue, Shock & Vibration

- Harmonic Analysis

- Crash Analysis

- Contact Stress Analysis

- Pressure Analysis

- Steady State Thermal Analysis

- Linear and Non-Linear Buckling Analysis

- Drop Test Analysis

- Flexible Dynamic Analysis

Areas & Activities:

- Steady State & Thermal transient

- Cyclic service

- Structural Stability and Rigidity

- Dead Load conditions

- Braking and Accelerating & Decelerating forces

- Centrifugal Loads

- Fatigue life estimates including creep

- Failure analysis

- Pressure Vessels – ASME Sections

- Flow induced & Vibration stability

CFD (Computational Fluid Dynamics) Analysis:

- Air flow conditions and patterns

- Thermal distribution